Dimensioning of control valve - Part 2 STEAM & GAS

We complete the technical notes for proper sizing of the DN of a valve with the following types of fluid: saturated steam, subsonic and sonic gases and vapors.

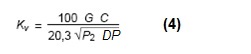

D) Saturated steam

with the following formula:

where:

- G = flow rate in Kg / h

- C = 1 + 0.0013 (t1 - t2)

- t1 = saturated steam temperature @ P1 pressure

- t2 = saturated steam temperature @ P2 pressure

- P1 = upstream absolute pressure in kPa

- P2 = downstream absolute pressure in kPa

- DP = pressure drop in kPa (P1-P2)

E) Gas and vapors

For these fluids, we have to distinguish two flow regimes: subsonic and sonic.

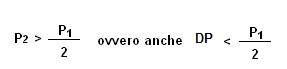

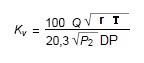

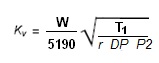

Subsonic regime

where:

and when do not reach the critical pressure ratio

when the flow reaches the speed of sound.

Flow rate:

where:

- Q = flow rate in Nm3 / h @ 0 °C

- r = density in kg / dm3 @ 0 °C and atmospheric pressure

- P2 = downstream absolute pressure in kPa

- DP = pressure drop in KPa

- T = absolute temperature upstream in °K

Mass flow:

where:

- W = flow rate in kg / h

- r = density in kg / dm3 @ 0 °C and atmospheric pressure

- P2 = downstream absolute pressure in kPa

- DP = pressure drop in KPa

- T1 = absolute temperature upstream in °K

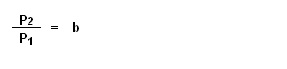

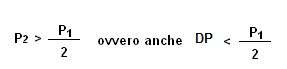

Sonic regime

and reaching or exceeding the critical pressure ratio

ie the flow reaches the speed of sound

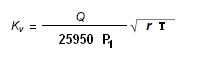

Flow rate:

where:

- Q = flow rate in Nm3 / h @ 0 °C

- r = density in kg / dm3 @ 0 °C and atmospheric pressure

- P1 = upstream absolute pressure in kPa

- T = upstream absolute temperature in °K

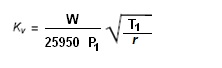

Mass Flow:

where:

- W = flow rate in kg / h

- r = density in kg / dm3 @ 0 °C and atmospheric pressure

- P1 = upstream absolute pressure in kPa

- T1 = upstream absolute temperature in °K

The technical notes indicated above are a summary of the general theory of fluid thermodynamics.

Our technicians are available to select and properly calculate the suitable control valve.

Posted in: Technical Library